Catalogs & operating instructions

Here you can download catalogs and operating instructions for various Erwin Sattler models and other well-known manufacturers from Germany and England as PDF files

Erwin Sattler Catalog

“In our manufactory in Gräfelfing near Munich, our highly qualified employees develop and create wonderful large clocks that combine timeless design with the highest quality and state-of-the-art technology. The timepieces become valuable companions that can be proudly passed on to future generations thanks to their longevity. In this catalog, we would like to introduce you to the wonderful world of Erwin Sattler products, which offers clock lovers a versatile range of valuable pieces of jewelry – whether on the wrist, in living rooms, as a high-quality storage option or as a piece of furniture. Let us inspire you! “

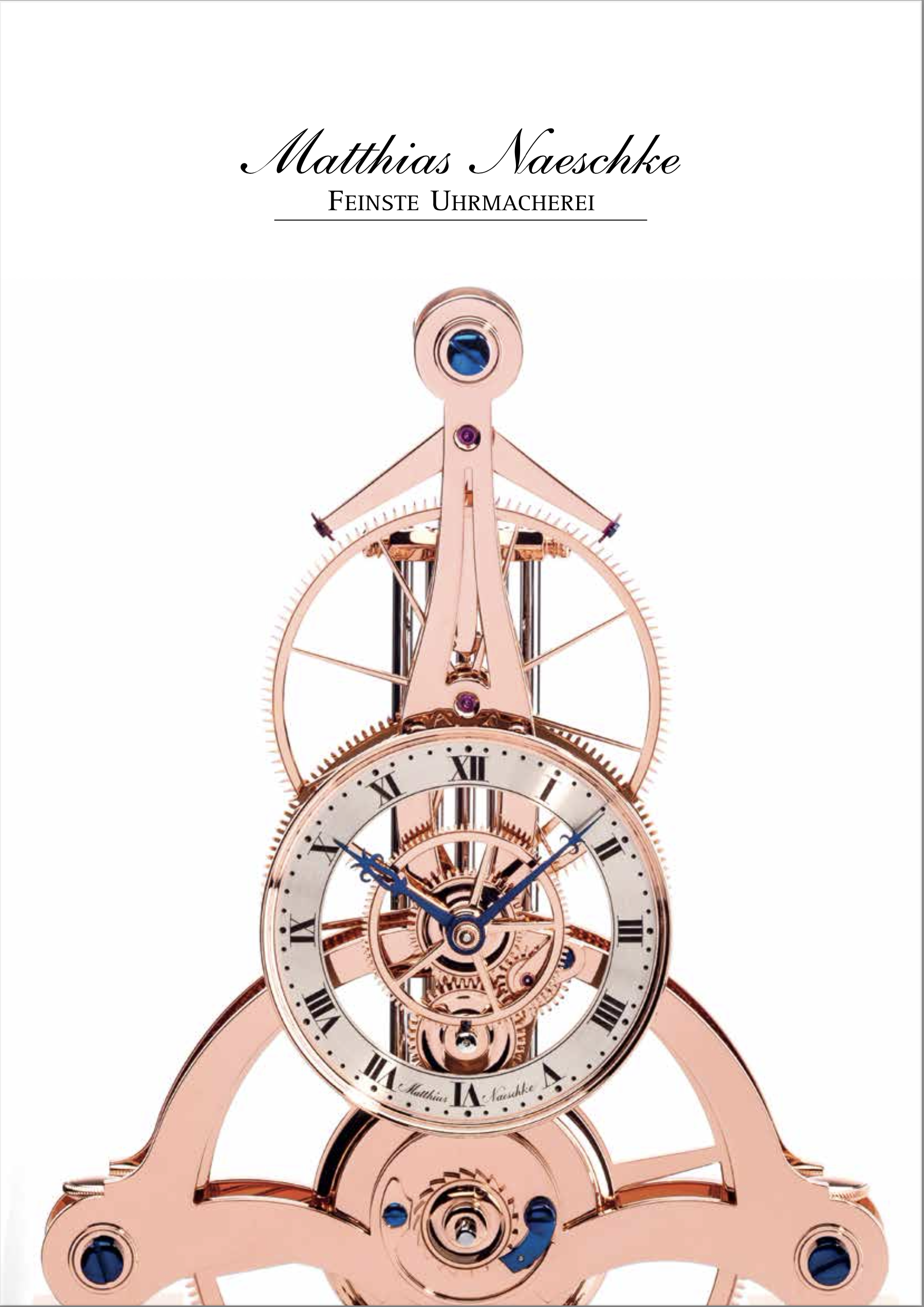

Matthias Naeschke Catalog

Finest quality, timeless elegance, highest precision. The highest maxim of our clock manufacturer is to build the best living room clocks. Since 1984, we have been producing the highest quality grandfather clocks, table clocks, regulators and, unique in the world, flute clocks and organ clocks. The strength of our traditional company is the precision craftsmanship of its production, the extremely high vertical range of manufacture and the realization of new ideas in classic clockmaking.

Sinclair Harding Catalog

Sinclair Harding was originally founded by Bill Sinclair and Mike Harding (1967-1995) with headquarters in Cheltenham, England. During this time over 700 clocks were produced. Bill Sinclair retired in 1971 and Mike Harding continued to work, developing the grandfather clock, the perpetual calendar and the popular sea clock.

In 1975 Mike Harding worked with Tim Bazley to develop the strike train, followed by the Bracket Clock and the Three Train Fusee movement. Sinclair Harding worked on a number of public commissions including the Wishing Fish Clock at Cheltenham and a Congreve Clock for 7 Ages of Man.

In 1995, Robert Bray (Bob) was looking for a new challenge and was introduced to Mike Harding by his uncle Brian Kitson, also an engineer and clock enthusiast. The company was a week away from closure, with no orders and no workforce. Bob had four young children and no idea about clockmaking – the challenge was daunting. Undeterred, he decided to take over the business and focus his skills on the art of clockmaking – or as Bob described it to BHI: “The gears going backwards.

From the beginning, Bob’s simple goal was to be completely independent and be able to make every part for every clock himself. His goal was to make clocks that would put a smile on his customers’ faces and bring joy to clockmakers in the future. The goal of making every part himself was achieved in 2017. His customers always smile when they see their clocks for the first time, and only time will tell if the third goal is achieved.

In 26 years and more than 1000 clocks later, Bob has personally been involved in or overseen the introduction of all proprietary capabilities:

Precious metal plating, production of scroll chains, production and manual tuning of bells, polishing, engraving and manual silver-plating of dials, blueing of screws and hands, even the production of mainsprings – to name but a few.

Today, the team at Sinclair Harding consists of 9 employees (mainly from the family), all of whom are involved in many processes in production. With our flexible team, we are constantly improving our efficiency and standards. This intense process of craftsmanship creates a clock that is aesthetically pleasing and reliable, with real soul and character, hopefully helping to ensure a secure future for English clockmaking.

The jumping second – an exceptionally exclusive complication

Pendulum clocks always have it…. the second hand, which jumps from one index to the next in time with the pendulum belonging to the clock. The length of a pendulum and thus its frequency determines the number of steps or jumps of the second hand per revolution, i.e. per minute……